Like a glue gun attached to a robot’ – that’s how Matthew Watkins, founder of Tauranga’s Special Studio, describes 3-D printing to me. Obviously there’s more to it than that but Matthew is keeping it simple and starting with the ‘what’, the ‘how’ and the ‘where’.

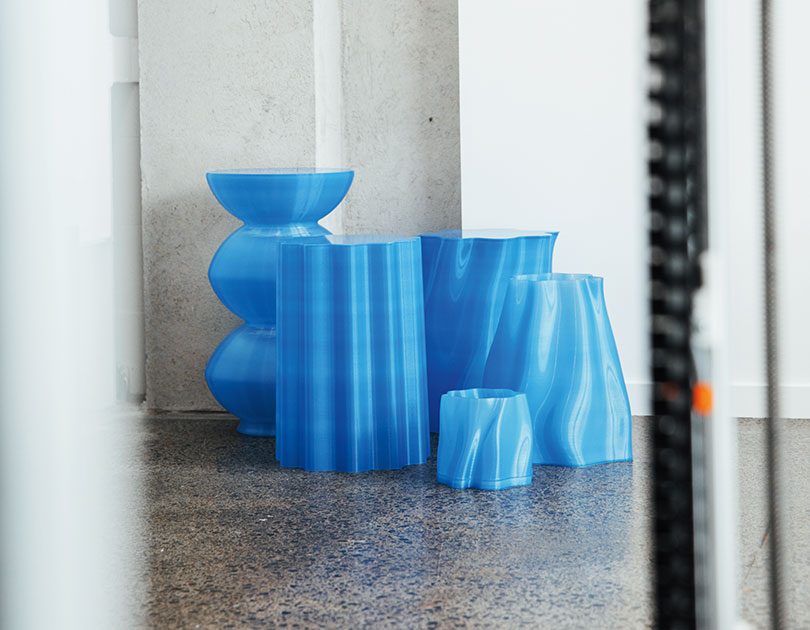

“Special Studio grew out of the question, ‘What’s the most efficient way to make stuff?’. The ‘what’ is our materials, and for us that had to be waste products. That meant the process (the ‘how’) had to be something that was compatible with using those recycled waste products. We wanted to manufacture locally in New Zealand, so we had to use automation to lower the labour component.” What brings all those together is 3-D printing, which enables Special Studio to use recycled waste plastic to create stools, planters, side tables and plinths.

While the perils of single-use plastic are well publicised and the aim to use fewer new plastic products is being heard, the question remains of what should be done with the plastic that is already here? Special Studio tackles the problem from both ends, using waste plastic as a raw material (the #7 plastics that can’t go in your recycling bin) and making products that can be recycled again and again. Indeed, the promise is that if you return a Special Studio product when you have finished with it, it will be resold or recycled into new objects (and you get a discount towards a new purchase).

Initially the waste plastic had to be imported from the Netherlands, but now about half is sourced locally. Matthew has even tried using scraps of plastics he picked up off the ground – it works, though the finished quality is not as good, so it could be used for products to be upholstered. In the process Matthew has become not only an expert designer, but expert at designing and building the 3-D printers themselves. Special Studio now has 11 printers including the largest one in New Zealand.

Learning to use a new technology frees up the design process, too. “It’s a ‘free-to-fail’ environment,” says Matthew. “Usually you play it safe because it is expensive to fail. But because we can feed our materials back into the machine, the cost of our failures can be absorbed.”

All of which has led to a design studio with the aim to use old things to make new things, to stop plastic killing the planet and bring useful, beautiful products to life. specialstudio.co Tracy Whitmey

SEE MORE FROM CUISINE

Design File / Jessica Crowe / stylist, painter / Whangamatā

Though you may not know Jessica Crowe’s name, if you are a regular…

Design File / Mark Mitchell / Ceramic artist / Northland

In his Northland studio, Mark Mitchell crafts ceramic pieces that use…

Design File / Sara Bruce / Exhibit A / Auckland

The contents in a cold glass should be savoured. Having one superb…

Design File / Janel Reid / Okay Ceramics / Auckland

Being nestled away in the peaceful Waitakere Ranges bestows an…